This is Part Two of a two part post looking at the collection of the Australian Armour and Artillery Museum that I visited on the ninth leg of our Australia trip, after arriving a Cairns in late January early February 2023.

As with Part One, this is a long long post to allow me to give a comprehensive overview of this very impressive collection, that seems to be added to each and every month, so if WWII German and Cold War tanks and guns 'float your boat' I suggest making a brew or something stronger if it's your preference, and I hope enjoy the read and accompanying pictures.

|

| Our route so far on our travels through Australia, starting down in Melbourne just before New Year 2023. Map courtesy of https://www.freeworldmaps.net/australia/ |

The link below will take you to Part One if you would like to follow things sequentially and where I have attached a link to the previous post in this series, entitled 'JJ's On Tour', which as a series covers our four month expedition across the Pacific Area October 2022 to February 2023.

|

| JJ's on Tour - The Australian Armour and Artillery Museum (Part One, WWII British & Empire, Japanese, Soviet-Russian and US Equipment) |

German WWII Vehicles & Guns

German Panzer 38T Light Tank

Developed in Czechoslovakia by ČKD, the type was adopted by Nazi Germany following the annexation of Czechoslovakia. With the German Army and other Axis forces, the type saw service in the invasions of Poland, France and the USSR. Production ended in 1942, when its main armament was deemed inadequate. In all, over 1,400 Pz. 38(t)s were manufactured. The chassis of the Pz. 38(t) continued to be produced for the Marder III (1942–1944) with some of its components used in the later Jagdpanzer 38 (1944–1945) tank destroyer and its derivative vehicles.

The two-man turret was centrally located, and housed the tank's main armament, a 37 mm Skoda A7 gun with 90 rounds of ammunition. In addition, a 7.92 mm machine gun was in a ball mount to the right of the main gun. This machine gun could be trained on targets independently of the main gun, or coupled to the main gun for use as a conventional coaxial machine gun.

The engine was mounted in the rear of the hull and powered the tank through a transmission at the front of the hull with five forward gears and one reverse gear. The track ran under four rubber-tyred road wheels and back over a rear idler and two track return rollers. The wheels were mounted on a leaf-spring double-bogie mounted on two axles.

This vehicle was rebuilt from battlefield relics acquired on the Eastern Front and represents the most common type of the 13 variations of Panzer III.

The introduction of the Ausf E into service with the German Army in late 1940 allowed every medium tank company to reach a strength of ten Panzer IVs for the fighting in the Balkans, North Africa and at the start of the invasion of Russia.

In 1941, the seventeen Panzer Divisions that took part in the invasion of Russia contained 438 Panzer IVs ranging from Ausf Bs to Fs.

This exhibit was acquired by the museum as a destroyed relic and has been restored in its current condition by the museum workshop.

To simplify production, the vision ports on either side of the turret and the loader's forward vision port in the turret front were removed, while a rack for two spare road wheels was installed on the track guard on the left side of the hull. Complementing this, brackets for seven spare track links were added to the glacis plate.

Despite addressing the mobility problems introduced by the previous Panzer IV, Ausf. H model, the introduction of the Panzer IV, Ausf. J, was considered a retrograde step by the Panzer units that used it.

With the urgent need to replace heavy battlefield losses resulted in the simplification of the manufacturing processes to speed up production at the cost of performance on the battlefield.

The Panther was a German World War II medium tank designed to counter the Soviet T-34 medium tank and to replace the Panzer III and Panzer IV.

Unlike most German tanks the naming of Panther production variants did not follow alphabetical order: the initial variant, Panther "D" (Ausf. D), was followed by the Ausf. A and then the Ausf. G variants.

The improved version, the Panther Ausf. A, entered production in August 1943. The major modifications including a better turret with a new commander's cupola, increased turret traverse speed, a mounting bracket for an anti-aircraft MG34 on the cupola, and a ball mounted MG34 in the frontal plate.

Though officially classified as a medium tank, its weight is more like that of a heavy tank and its weight at 44.8 metric tons puts it roughly in the same category as the American M26 Pershing (41.7 tons), British Churchill (40.7 tons) and the Soviet IS-2 (46 tons) heavy tanks.

Parts of Tiger tanks are not easy to find these days and parts that have not been destroyed are even harder, and the fabrication of damaged existing parts has to be seen to be believed. The hull alone took a year of work to reconstruct. and it took five years to acquire all the parts necessary before the rebuild commenced in 2020.

Production of the Tiger I began in August 1942 at the factory of Henschel und Sohn in Kassel, initially at a rate of 25 per month and peaking in April 1944 at 104 per month. An official document of the time stated that the first Tiger I was completed on 4 August and 1,355 had been built by August 1944, when production ceased. Deployed Tiger I's peaked at 671 on 1 July 1944.

Eager to make use of his powerful new weapon, Hitler ordered the new tank into service months before it was planned to be phased in after the necessary time to deal with the teething problems that accompanied the introduction of a new vehicle.

After the Germans encountered the Soviet KV-1 and T-34 tanks, the StuG was reequipped with a high-velocity 7.5 cm StuK 40 L/43 main gun (spring 1942) and in the autumn of 1942 with the slightly longer 7.5 cm StuK 40 L/48 gun.

Seen here are the additional 30 mm armour plates that were welded to the 50 mm frontal armour from June 1942, making the frontal armour 80 mm thick.

Firing armour-piercing Panzergranat-Patrone 39, the StuK 40 L/43 could penetrate 91 mm of armour inclined 30 degrees from vertical at 500 m, 82 mm at 1,000 m, 72 mm at 1,500 m, 63 mm at 2,000 m, allowing the Ausf. F to engage most Soviet armoured vehicles at normal combat ranges.

In addition to 26 high explosive shells, a combat load for a StuH 42 also contained 10 hollow charge anti-tank projectiles which could penetrate 90-100 mm of armour.

The Sturmgeschütz IV resulted from Krupp's effort to supply an assault gun. As Krupp did not build Panzerkampfwagen IIIs, they used the Panzerkampfwagen IV chassis in combination with a slightly modified Sturmgeschütz III superstructure.

The Jagdpanzer IV used a modified Panzer IV Ausf. H tank chassis, with 80mm sloped armour plates on the front replacing the tank's almost vertical 100 mm front hull plate.

Installing the much heavier Pak 42 meant that the Jagdpanzer IV was nose-heavy, especially with the heavy frontal armour. This made them less mobile and more difficult to operate in rough terrain, leading their crews to nickname them Guderian-Ente ("Guderian's duck"). To prevent the rubber rims of the roadwheels being dislocated by the weight of the vehicle, some later versions had steel roadwheels installed on the front.

The final prototype of the Jagdpanzer IV was presented in December 1943 and production started in January 1944, with the Pak 39 L/48 armed variant staying in production until November. Production of the Pak 42 L/70 armed variants started in August and continued until March/April 1945.

The Jagdpanzer IV served in the anti-tank sections of Panzer and SS Panzer divisions. The vehicle fought against Western Allied forces in Normandy and the Battle of the Bulge, and Soviet tanks and troops on the Eastern Front.

The Jagdpanzer 38 first entered service with the Heeres Panzerjäger-Abteilung 731 in July 1944, and saw continuous service until the end of the war.

The Jagdpanzer 38 was one of the lighter category of German tank destroyers that began with the Panzerjäger I, continued with the Marder series, and ended with the Jagdpanzer 38.

The Jagdpanzer 38 was one of the most common late-war German tank destroyers. It was available in relatively large numbers and was generally mechanically reliable. and had a remote-control machine gun mount that could be fired from within the vehicle.

The 75 mm Pak 39 L/48 gun of the Jagdpanzer 38 was a modified version of the 75 mm StuK 40 L/48 used in the StuG III and StuG IV assault guns. With this gun, the Jagdpanzer 38 was able to destroy nearly all Allied or Soviet tank types in service at long ranges (except heavy tanks), and its fully enclosed armour protection made it a safer vehicle to crew than the open-topped Marder II or Marder III series.

Its small size made it easier to conceal than larger vehicles. It was not intended for a mobile, meeting engagement or the typical Wehrmacht blitzkrieg style of warfare. It rather excelled when emplaced along pre-determined lines of sight where the enemy was expected to approach and when used in defensive positions to support a prepared ambush.

Its main failings were comparatively thin side armour, limited ammunition storage, poor gun traverse, and a poor internal layout that made operating the vehicle difficult, as well as leaf springs and drive wheels that were prone to failure due to the increased weight.

The Jagdpanther was armed with the long-barrelled 8.8 cm Pak 43/3 L/71 gun, similar to the main gun of the Tiger II ("King Tiger"). The gun was mounted in a central mantlet, giving it a limited traverse of twelve degrees to each side.

The Jagdpanther was preceded by two attempts at mounting an 8.8 cm gun as a self-propelled anti-tank weapon; the Ferdinand proved to be too heavy, and Nashorn lightly armoured and under-powered.

There were two main variants. The earlier G1 1944 model had a small welded main gun mantlet, one-piece Pak 43/3 gun, a modified Panther A engine deck, and had two vision openings for the driver.

A total of 415 Jagdpanthers were produced from January 1944 by three manufacturers: MIAG in Braunschweig produced 270 from January 1944 until the end of the war, Maschinenfabrik Niedersachsen Hannover (MNH) produced 112 from November 1944, Maschinenbau und Bahnbedarf (MBA) in Potsdam produced 37 vehicles from December 1944.

The last 'production' Jagdpanthers were produced at the factory just after the end of World War II by German staff under the supervision of the Royal Electrical and Mechanical Engineers (REME) during the American and British occupation of Germany. Nine Panthers and a dozen Jagdpanthers were produced, then shipped to England for evaluation.

The usual forward mounted machine gun of the Sd.Kfz. 251 was replaced with a short barrelled low velocity 75 mm L/24 howitzer, which was the same gun and mounting used on the StuG III's and Panzer IV's.

The first two models (Ausf. A and B) were produced in small numbers from 1939. Ausf. A and B models can be identified by the structure of the nose armour, which comprised two trapezoidal armour panels. The B model, which began production in 1940, eliminated the fighting compartment's side vision slits. The C model, which started production in mid-1942, featured a simplified hexagonal-shaped forward armoured plate for the engine. Models A through C had rear doors that bulged out. The C model had a large production run, but was quite complex to build, involving many angled plates that gave reasonable protection from small arms fire.

The range of the gun allowed the vehicle to be used in a relative safety from well camouflaged, pre-arranged positions.

The chassis was never designed to cope with the extra weight of the Pak 40 gun. This combined with the blast shock and recoil triggered many mechanical breakdowns and excessive structural fatigue.

This exhibit was acquired in the UK and like many surviving OT-810s has been painted to resemble an Sd.Kfz. 251 for use in military re-enactment's.

Production of this early version stopped in October 1943 with some 4,200 built and the complex body-shape dropped in favour of a neue art (new version) with flattened crew compartment sides made from a single piece of armour. This greatly simplified manufacture but in both variants the level of protection was minimal - rifle-calibre small-arms fire and shell fragments would likely be stopped, but heavy machine guns, anti-tank rifles and virtually any form of artillery could perforate the Sd.Kfz. 250 even at long range.

German Sd.Kfz. 250/8 Ausführung B Halftrack (7.5cm K51 Gun)

The Sd.Kfz. 250/8 support variant was armed with a 7.5cm KwK 37 L/24 gun as used in the early Panzer IVs and an MG 34.

German Sd.Kfz. 250/3 Ausführung B Halftrack (Command Variant)

The vehicle was restored by by Axis Track Services in the UK.

The driver was in the front right of the hull, with the radio operator seated to the driver's left. The radio operator manned the hull-mounted 7.92 mm machine gun in front in addition to operating the radio on his left.

In German service, a loader position was added to the turret by reducing the ammunition capacity by 18 rounds. All future Panzer 38(t) tanks were rebuilt according to this specification and those already in service were modified accordingly. The commander had to aim and fire the main gun in addition to his role as commander.

The engine was mounted in the rear of the hull and powered the tank through a transmission at the front of the hull with five forward gears and one reverse gear. The track ran under four rubber-tyred road wheels and back over a rear idler and two track return rollers. The wheels were mounted on a leaf-spring double-bogie mounted on two axles.

The museum have a short video, link below, showing this wonderful exhibit being started up and given a short drive in preparation for AusAmourfest.

German Panzer IV Ausführung D & Panzer III Ausführung J

The Panzerkampwagen IV Ausf. D was commonly known as the Panzer IV D and was the fourth version of the Panzer IV series and the first variant to be produced during the Second World War.Two-hundred and forty-eight Panzer IV Auf D's were ordered in 1938, seeing just 232 built when production ended in about October 1940, which makes this a very beast indeed and such a thrill to see one this close up.

Built on the same dimensions as the previous models (Ausf. B and C) the D saw the reintroduction of the hull machine gun and the protruding drivers plate and changed the turret's internal gun mantlet to a 35 mm (1.38 in) thick external mantlet as opposed to 30mm on the Ausf C.

As I was about to take a closer look at the Panzer III J, close alongside, my camera battery packed up, and Alex introduced himself and we began talking about the collection, and in my distractedness I later found I only had a partial view of the III J in the picture of the IV D above and so for completeness I have linked to the video walk around provided by mulligan64 on his YouTube Channel.

German Panzer IV Ausführung E

The Panzer IV Ausführung E was introduced in October 1940, and was the fifth production model of the Panzer IV medium tank which would see a significant increase in armour carried by the tank compared to the Ausf D. This saw 30 millimetres (1.18 inches) of armour on the bow plate, while a 30-millimetre (1.18 inches) appliqué steel plate was added to the glacis as an interim measure. A new driver's visor, adopted from the Sturmgeschütz III was installed on the hull front plate. A new commander's cupola, adopted from the Panzer III Ausf. G, was relocated forward on the turret eliminating the bulge underneath the cupola.

Older model Panzer IV tanks were retrofitted with these features when returned to the manufacturer for servicing, and up to 206 Ausf. Es were produced between October 1940 and April 1941.

|

| This careful restoration has seen the uncovering and protection of the original paintwork and markings revealed during the rebuild in their original positions on the tank. |

The Ausf E remained in service until the last examples became unserviceable or were destroyed in 1944.

German Panzer IV Ausführung G

On 26 May 1941, just before Operation Barbarossa, it was decided to improve the Panzer IV's main armament.

In November 1941, the decision to up-gun the Panzer IV to the 50-millimetre (1.97 in) gun was dropped, and instead Krupp was contracted in a joint development to modify Rheinmetall's pending 75 mm (2.95 in) anti-tank gun design, later known as 7.5 cm Pak 40 L/46. Because the recoil length was too great for the tank's turret, the recoil mechanism and chamber were shortened. This resulted in the 75-millimetre (2.95 in) KwK 40 L/43.

The Ausf. F tank that received the new, longer KwK 40 L/43 gun were temporarily named Ausf. F2.

When the new KwK 40 was loaded with the Pzgr. 39 armour-piercing shell, the new gun fired the AP shell at some 750 m/s (2,460 ft/s), a substantial 74% increase over the howitzer-like KwK 37 L/24 gun's 430 m/s (1,410 ft/s) muzzle velocity. Initially, the KwK 40 gun was mounted with a single-chamber, ball-shaped muzzle brake, which provided just under 50% of the recoil system's braking ability. Firing the Panzergranate 39, the KwK 40 L/43 could penetrate 77 mm (3.03 in) of steel armour at a range of 1,830 m (6,000 ft).

.jpg) |

| Panzer IV Ausf. G in the Russian winter https://www.panzernet.net/panzernet/stranky/tanky/pz4.php |

Three months after beginning production, the Panzer IV Ausf. F2 was fitted with an improved muzzle break and was renamed the Panzer IV Ausf. G, and during its production run rom March 1942 to June 1943, the Panzer IV Ausf. G went through further modifications, including another armour upgrade which consisted of a 30-millimetre (1.18 in) face-hardened appliqué steel plate welded (later bolted) to the glacis.

This exhibit was acquired by the museum as a battlefield relic and has been restored in its current condition by the museum workshop.

German Panzer IV Ausführung J

The Panzer IV, Ausf. J was the final production version of the Panzer IV series of German tanks produced in World War II.

Modifications included:

- The electric generator that powered the tank's turret traverse was removed, so the turret had to be rotated manually.

- The manual turret traversing mechanism was modified and fitted with a second gear which made hand-operation easier.

- The resulting space from the removal of the generator was later used for the installation of an auxiliary 200-litre (53 US gal) fuel tank; road range was thereby increased to 320 km (200 miles).

- The engine's radiator housing was simplified by changing the slanted sides to straight ones.

- The number of return rollers was reduced from four to three.

- The cylindrical muffler was replaced by two flame-suppressing mufflers.

This exhibit was acquired by the museum as a Eastern Front battlefield relic and has been restored in its current condition by the museum workshop, displaying the 'Thoma Schuzen' (wire mesh screens) that were designed to disrupt the trajectory of enemy anti-tank rounds to reduce their ability to effectively penetrate the side armour of the tank.

Again with regard to the unique collection of Panzer IV models, the museums has produced an interesting video review of their collection, link below.

German Panther Ausführung A

Of course one of the star exhibits right next to the other one, seen below, immediately caught my attention on entering the display gallery, but in the spirit of delayed gratification only adding to the experience I resisted making an immediate beeline to this very special and rare tank.Production of the Panther Ausf. D commenced in January 1943 and they first saw combat during the Battle of Kursk in July/August 1943. Initially there were significant technical problems that effected the reliability of the Panther because they had been rushed into service.

As the war progressed there were a number of issues that impacted the tank's effectiveness. These included the bombing of production plants, increased shortages of material, and a lack of fuel and adequately trained crews.

The Panther was the first German tank to have sloped armour which increased the effective thickness of the armour from 80mm (3.1 inches) to roughly 140mm (5.5 inches), effectively making the front of the tank impervious to enemy fire. However the sides of this tank were very vulnerable, ranging from only 40mm (1.6 inches) to 50mm (2 inches) of either barely sloped or completely flat armour.

This exhibit was acquired from the UK and then underwent a full four-year restoration prior to arriving at the museum.

Research has identified that:

- The hull and turret were fabricated by the Hermann Goring Steel Works in Linz, Austria, but the final factory it was assembled in is unknown.

- The tank was probably used by the 12th SS Panzer Division in Normandy after the 1944 D-Day invasion.

- Post-World War II the tank was refurbished by the AMX factory prior to service with the French Army.

- This tank served with the French 501-503rd Regiment de Char de Combat before it was disposed of to the Saumur Tank Museum. (Now there lies a story about how this very very rare tank ended up being relocated from Saumur to Cairns, Australia).

- The Panther was restored to its current condition by Axis Track Services in the UK.

You can follow the fascinating story of the completion of this restoration project in the video link below.

German Panther Ausführung D Glacis Plate

This Panther Ausführung D Glacis Plate was recovered from the battlefields on the Eastern Front and carries traces of Zimmerit anti-magnetic paste together with original paint and illustrates well one of the key changes between the Ausf. D and later Ausf. A seen above with the 'letter box' style of machine gun port seen here as opposed to the ball mount that replaced it.

German Tiger 1 Ausführung E

There are today only nine Tiger I tanks surviving in museums and private collections worldwide. As of 2021, Tiger 131 (captured during the North Africa Campaign) at the UK's Tank Museum is the only example restored to running order.This amazing exhibit is the result of hours of painstaking work piecing together multiple parts of armour plating, much of which needed stress cutting and pressing back into shape before it could become an addition to the jigsaw puzzle of seeming scrap iron that has been transformed into perhaps the most famous or should that be infamous tanks of World War II, the Tiger heavy tank.

Most of the tank came from one Tiger with other parts salvaged from other Tiger tanks to keep the fabrication of parts to a minimum.

|

| An early production model Tiger tank in action near Leningrad, displaying the early model cupola. |

A platoon of four Tigers went into action on 23rd September 1942 near Leningrad. Operating in swampy, forested terrain, their movement was largely confined to roads and tracks, making defence against them far easier. Many of these early models were plagued by problems with the transmission, which had difficulty handling the great weight of the vehicle if pushed too hard.

Early Tigers had a top speed of about 45 km/h (28 mph) over optimal terrain. This was not recommended for normal operation, and was discouraged in training. An engine governor was subsequently installed, capping the engine at 2,600 rpm and the Tiger's maximum speed to about 38 km/h (24 mph). Tiger crews report that typical march speed off-road was 10 km/h (6 mph).

The Tiger was originally designed to be an offensive breakthrough weapon, but by the time it went into action, the military situation had changed dramatically, and its main use was on the defensive, as a mobile anti-tank and infantry gun support weapon.

Arranged around the Tiger rebuild was a selection of other Tiger components not used for one reason or another, usually because of extensive damage, with better examples being used instead.

These unused parts are placed alongside the reconstructed vehicle to illustrate the armour thicknesses, and the various parts of the tank and are an excellent exhibit to better illustrate the protection afforded to Tiger crews.

As seen below and on the other reconstructed vehicles, discovered original paintwork and markings are carefully preserved amid the reconstructed camouflage paint and this also extends to original battle damage, with the rear armour around the engine deck below displaying a hit and splatter damage from a light armour piercing round that had nowhere to go when it hit the original Tiger.

It was great to see the Tiger, a relatively new addition to the display hall, and one to compare with those at Bovington and Saumur.

However, medium tanks of the time, such as the Sherman or T-34, had on average a top speed of about 45 km/h (28 mph). Thus, despite the Tiger being nearly twice as heavy, its speed was comparatively respectable.

The average reliability of the Tiger tank in the second half of 1943 was similar to that of the Panther, 36%, compared to the 48% of the Panzer IV and the 65% of the StuG III.

From May 1944 to March 1945, the reliability of the Tiger tank was comparable to the Panzer IV. With an average of 70%, the Tiger's operational availability on the Western Front, was better than 62% of Panthers.

On the Eastern Front, 65% of Tigers were operationally available, compared to the 71% of Panzer IVs and 65% of Panthers.

The Tiger was originally designed to be an offensive breakthrough weapon, but by the time it went into action, the military situation had changed dramatically, and its main use was on the defensive, as a mobile anti-tank and infantry gun support weapon.

Tactically, this also meant moving the Tiger units constantly to parry breakthroughs, causing excessive mechanical wear. As a result, Tiger battalions rarely entered combat at full strength.

The museum have put together a video presentation of the build process for their Tiger and is well worth watching to understand the skill and ingenuity required to build a Tiger tank from scraps of original parts - truly inspiring.

German Maybach HL 120 TRM Engine

During the Second World War, the Maybach Motorenbau Company produced the engines for most of Germany's tanks including the Panzer I, II, III and IV, the Tiger I and II whilst alsoi producing engines for half-tracks such as the Sd.Kfz 251 and 250 personnel carriers and prime movers like the Sd.Kfz 9.The Maybach HL120 TRM was a 12 cylinder, liquid cooled petrol engine with an output of 330 hp or 220 kw and was used to power the Panzer III, IV (Ausf. C onwards) and the Hummel self propelled gun.

This exhibit was acquired from Czechoslovakia and shows extensive battle damage caused by fire, explosions, and projectile impacts.

German Early Production Tiger Tank Turret Roof

This early model Tiger I turret roof and commander's cupola show the effects of a catastrophic internal explosion in the turret, likely either caused by being hit by enemy fire or the crew destroying the tank after mechanical failure had forced its abandonment and thus needing to avoid it falling into enemy hands.Early production turret roofs, as revealed here, were only 30mm thick and left the tank vulnerable to artillery fire, with late production Tigers having a roof thickness increased to 60mm.

This exhibit was acquired from the Ukraine.

German Sturmgeschütz III Ausführung A

The Sturmgeschütz III (StuG III) assault gun was Germany's most-produced fully tracked armoured fighting vehicle during World War II, and second-most produced German armoured combat vehicle of any type after the Sd.Kfz. 251 half-track.It was built on a slightly modified Panzer III chassis, replacing the turret with a fixed armoured superstructure mounting a more powerful gun.

Initially intended as a mobile assault gun for direct-fire support for infantry, the StuG III was continually modified, and was employed successfully as a tank destroyer.

This exhibit was acquired from Czechoslovakia and is the only StuG II Ausf. A of the 36 made in early 1940 known to exist.

Research indicates that it belonged to Sturmgeschutz Battery 660 and was lost as it attempted to cross the Shosha River in the Tula region of Russia.

|

| Stugs of Sturmgeschutz Abteilung 192 displaying their Totenkopf emblem |

The Totenkopf (death's head) emblem on the superstructure denotes it as belonging to Sturmgeschutz Abteilung 192 which was one of the units that took part in Operation Barbarossa and later saw action at the Battle of Smolensk and the Battle of Moscow.

German Sturmgeschütz III Ausführung F

Believed to be the only existing StuG Ausf. F and thought to have been operated by Sturmgeschutz Abteilung 244 in Stalingrad from November 1942 to February 1943, where the German 6th Army and this battalion were destroyed.

These high-velocity guns were the same as those mounted on the Panzer IV for anti-tank use. These versions were known as the 7.5 cm Sturmgeschütz 40 Ausf.F, Ausf. F/8 and Ausf. G (Sd.Kfz.142/1).

Below is the link to the museum's video featuring this particular vehicle.

German Sturmhaubitze 42

German Sturmhaubitze 42

The Sturmhaubitze 42 (StuH 42) was a World War II German self propelled gun built on the battle proven chassis of the Sturmgeschütz III Ausf. F/8 and G assault guns.

The StuH 42was developed in 1942 and was designed to provide the Wehrmacht with effective combat support against infantry and infantry fortifications, but was also capable of performing an anti-tank role.

The StuH 42 saw extensive service with Sturmgeschütz detachments on both the Western and Eastern Fronts until the end of the war.

The barrel of the 10.5 cm L/28 howitzer was shorter, thicker and tapered more towards the muzzle than the muzzle of the 7.5 cm StuK 40 L/48 gun found on the StuG III variants, allowing it to deliver a much larger quantity of high explosive to the target.

Later models of the StuH 42 did not have a muzzle break attached to the barrel, simply to streamline production.

This exhibit was acquired from Czechoslovakia.

German Sturmgeschütz IV

The Sturmgeschütz IV (StuG IV) (Sd.Kfz. 167) was a German assault gun variant of the Panzer IV used in the latter part of the Second World War. It was identical in role and concept to the highly successful StuG III assault gun variant of the Panzer III.Initially they were intended as a mobile armoured gun platform, providing close fire support to the infantry to destroy bunkers, pillboxes and other entrenched positions. As the war progressed and the production of tanks was unable to keep up with the attrition number, they became a valued supplement to the Panzer forces on both the Western and Eastern Fronts.

|

| A StuG IV knocked out and abandoned in Normandy. I have a feeling that this is one of the StuG IV's operated by 17th SS Panzergrenadier Division during their failed counterattack on Carentan. |

The gun mantlet of the StuG IV was known as the 'Saukopf' or 'pig snout' and modifications included Zimmerit paste as seen here, a shielded MG 34 on the roof and Schurzen spaced armour.

This exhibit was acquired as a battlefield relic from the Eastern Front and rebuilt to its current condition by the museum workshop.

German Panzer IV/70 (V) "Jagdpanzer"

The Jagdpanzer IV/70 was a casemate-style turretless Jagdpanzer (tank destroyer, literally "hunting tank") developed against the wishes of Heinz Guderian, the inspector general of the Panzertruppen, as a replacement for the Sturmgeschütz III (StuG III).

Guderian objected against the needless, in his eyes, diversion of resources from Panzer IV tank production, as the StuG III was still more than adequate for its role.

The Jagdpanzer IV used a modified Panzer IV Ausf. H tank chassis, with 80mm sloped armour plates on the front replacing the tank's almost vertical 100 mm front hull plate.

Internally, the layout was changed to accommodate the new superstructure, moving the fuel tanks and ammunition racks.

To make the manufacturing process as simple as possible, the superstructure was made from large, interlocking plates that were welded together.

The final prototype of the Jagdpanzer IV was presented in December 1943 and production started in January 1944, with the Pak 39 L/48 armed variant staying in production until November. Production of the Pak 42 L/70 armed variants started in August and continued until March/April 1945.

|

| A well known picture of a Jagdpanzer IV/70 operating during the Battle of the Bulge in late 1944 |

It was very successful as a tank destroyer due to its low profile, accurate gun and good armour protection, but performed poorly when used out of role as a substitute for tanks or assault guns to support infantry.

This exhibit was rebuilt by the museum workshop using relics recovered from battlefields of the Eastern Front and sports the late war 'Ambush' camouflage scheme seen used during the German Bulge offensive codenamed Whact am Rhein (Watch on the Rhine).

German Jagdpanzer 38 (Sd.Kfz. 138/2) Hetzer ("baiter")

The Jagdpanzer 38 (Sd.Kfz. 138/2), commonly known as Hetzer, was a German light tank destroyer of the World War II based on a modified Czechoslovakian Panzer 38(t) chassis.The Jagdpanzer 38 was intended to be more cost effective than the much more ambitious Jagdpanther and Jagdtiger designs of the same period. Using a proven chassis, it avoided the mechanical problems of the larger armoured vehicles.

|

| A Jagdpanzer 38 Hetzer knocked out in Prague, during the fighting in May 1945 |

The vehicle seen here was acquired from a collector in Luxembourg, and its history shows it was manufactured in 1945 and saw service in the defence of Prague where it sustained battle damage.

It was returned to the workshop for repair but never again saw active service, later being modified and used by the Swiss Army.

The vehicle underwent an 18-month restoration project by Axis Track Services in the UK to restore it to its 1945 condition before delivery to the museum in March 2015.

The museum video below demonstrates the original engine being started up as well as look inside the crew compartment.

German Jagdpather Tank Destroyer

The Jagdpanther (German: "hunting Panther"), Sd.Kfz. 173, was a Gereman tank destroyer built by Germany during World War II.In October 1943 a full-size prototype built by Daimler-Benz was demonstrated to Hitler.

|

| Jagdpanthers in Normandy in the summer of 1944 |

|

| The Sd.Kfz. 184 Ferdinand 'Elefant' |

|

| The Nashorn (Rhinoceros) |

The G2 Jagdpanther used a Panther Ausf. G engine deck, a larger gun mantlet bolted externally, and a two-piece KwK 43/4 L/71 gun and a single vision opening for the driver.

This exhibit was rebuilt by the museum workshop from battlefield relics recovered from the Eastern Front and you can see a full length video of the rebuild in the video link below.

German Sd.Kfz. 251/9 Ausführung C Halftrack "Stummel"

The Sd.Kfz. 251/9 is a self propelled gun variant of a Sd.Kfz. 251 halftrack and was one of the many improvisations the Wehrmacht made to the Sd.Kfz. 251 halftrack family during the war.From 1942 each Panzergrenadier Battalion was supported by a platoon of Sd.Kfz. 251/9's which gave them fast and effective fire support when other fully tracked assault guns were not readily available.

The Sd.Kfz. 251/9 was nicknamed "Stummel" ("stump") and committed in great numbers on the Eastern Front, but also saw extensive service against the Allies after the D-Day landing.

The Sd.Kfz. 251/9 has provision to carry 52 rounds, but many extra rounds were carried whenever it was possible, notably on the rifle racks and crammed in extra soft bags.

This exhibit was acquired from Czechoslovakia.

German Sd.Kfz. 251/1 Ausführung D Halftrack Armoured Personnel Carrier

The Sd.Kfz. 251 (Sonderkraftfahrzeug 251) half-track was an armoured fighting vehicle designed to transport the Panzergrenadiers of the German mechanized infantry corps into battle. Sd.Kfz. 251s were the most widely produced German half-tracks of the war, with at least 15,252 vehicles and variants produced by various manufacturers. There were four main model modifications (Ausführung A through D), which formed the basis for at least 22 variants.

The initial idea was for a vehicle that could be used to transport a single squad of 10 panzer grenadiers to the battlefield protected from enemy small arms fire, and with some protection from artillery fire. The standard mounting of at least one MG 34 or MG 42 machine gun allowed the vehicle to provide suppressive fire support for the infantry squad once they had disembarked in battle.

From early 1943, the D model was developed with the purpose of halving the number of angled body plates, simplifying the design and thus speeding up the production. D models can be easily recognized by their single piece sloping rear, with flat doors.

This Sd.Kfz. 251/1 D was acquired from the UK and research on its chassis number 548730 indicates that the vehicle was made by the Auto-Union factory in Chemnitz, Germany in early December 1944.

German Sd.Kfz. 251/22 Pak 40

The Sd.Kfz. 251/22 was a German World War II medium sized armoured fighting vehicle with a 7.5cm Pak 40 anti-tank gun mounted in the back.

They were heavily used as the German operations turned into defensive actions, from Italy to Normandy and the Eastern Front.

In December 1944, Hitler gave this version of the Sd.Kfz. 251 top production priority and it is believed approximately 1200 of the vehicles were built using Sd.Kfz. 251 Ausf. D bodies.

The mount comprised to H shaped beams welded to the floor, on the middle of the rear compartment. The shield was modified with trimmed angles, and the platform was made of flat triangular plates holding in place the original gun cradle. Traverse was 18 to 19 degrees and elevation ranged from -3 to +22 degrees.

The vehicle was stored with twenty rounds of HE and AP and usually the crew carried extra rounds in loose containers, stored wherever there was suitable space.

This exhibit was acquired from Czechoslovakia.

Czech OT810 Armoured Personnel Carrier

The OT-810 Armoured Personnel Carrier is a variant of the World War II German Sd.Kfz. 251.The Czech Army utilized captured and abandoned German Sd.Kfz. 251s for their post-war armed forces, with these left over vehicles eventually wearing out and the need for replacement vehicles arose for which the OT-810 was created as a replacement.

The OT-810 Tatra and Skoda, both of whom were involved in the original construction of Wehrmacht Sd.Kfz. 251s, and design started in 1952, stopping in 1954, but then recommencing in 1956 with an initial batch of ten vehicles produced between 1958-59.

In the end the vehicle was accepted into service under the OT-810 designation ('OT' means 'Obrneny Transporter' or 'Armoured Transporter').

The vehicle was not very popular, being hard to control and providing a cramped infantry compartment together with a difficult maintenance reputation causing it to be nicknamed "Hitlerova pomsta" or "Hitler's revenge".

At least 2,400 OT-810's were built and used by the Czech armed forces until well into the 1980s and would see the vehicle enclosed with an armoured roof over the troop compartment for better protection from shrapnel and exposure to radiation or gas.

German Sd.Kfz. 250/3 Ausführung A Halftrack (Radio Variant)

The Sd.Kfz. 250 family of vehicles was a series of light armoured half-tracks, adopted in 1939 to supplement the standard Sd.Kfz. 251 halftracks.This vehicle is the early version of the Radio/Command variant and was used by battalion and higher level commanders.

The large 'bedframe' antenna was easy to spot at long range, making them more vulnerable to enemy fire.

The unit markings on the vehicle are larger than the standard size usually found and replicate those for the tactical markings of an headquarters vehicle from the Medium Reconnaissance Company of the 1st SS Panzer Division "Leibstandarte SS Adolf Hitler" (LSSH).

This exhibit was acquired from Czechoslovakia.

The Sd.Kfz. 250/8 support variant was armed with a 7.5cm KwK 37 L/24 gun as used in the early Panzer IVs and an MG 34.

The KwK 37 gun was later replaced by the slightly revised version under the designation 7.5cm K51 L/24.

The Sd.Kfz. 250/8 appeared for the first time in November 1943, but full production did not begin until March or April 1944 because of delays in the production of the K51 gun.

The small size of the vehicle and the size of the gun limited the crew to three men and only allowed for twenty rounds of 7.5cm ammunition to be carried.

To provide extra protection for the gun crew the normal front and side walls of the vehicle were raised with additional armour plates, however the installation of the gun and the added armour led to a significant upward shift of the centre of gravity which increased the likelihood of the vehicle overturning at speed or when traversing uneven ground.

The Sd.Kfz. 250/8 saw extensive action on the Eastern Front against the Russians and later against the Allies after the D-Day invasion, providing support to infantry units against fortified positions or light armoured vehicles in offensive and defensive operations.

This exhibit was acquired from Czechoslovakia.

The Sd.Kfz. 250/3 Ausführung B Halftrack represents the later development of the Ausf. A illustrated previously sporting its 'bedframe' antenna.

It had fewer seats but was equipped with long range radio equipment and likewise with the Ausf. A used by Battalion and higher level commanders as personal command vehicles.

Discarding the 'bedframe' antenna made these vehicles less conspicuous and the previous arrangement was replaced with whip antenna instead.

This exhibit was made in 1943 by Demag and was recovered from a forest on the Russian/Finnish border near the town of Kemijarvi, an area of Finland occupied by the SS Nord Division during World War II.

German Sd.Kfz. 11/1 Flak - Halftrack with Flak 38

The Sd.Kfz. 11 (Sonderkraftfahrzeug – special motor vehicle) was a German half-track that saw widespread use in World War II. Its main role was as a prime mover for medium towed guns ranging from the 3.7 cm FlaK 43 anti-aircraft gun up to the 10.5 cm leFH 18 field howitzer and it could carry eight troops in addition to towing a gun or trailer.The 2cm Flak 38 was mounted on an open flatbed and the mesh-like sides could fold out flat to allow the crew a wider platform to stand on when operating the gun.

The vehicle was restored by by Axis Track Services in the UK, and is the only example of this vehicle known to still exist.

German Raupenschlepper Ost 7.5cm Pak 40

The World War II German Raupenschlepper Ost (RSO) was a tracked vehicle based on the Steyr 1500A light truck. It was developed after fighting on the Eastern Front identified the need for a fully tracked light weight transport vehicle capable of dealing with the mud and snow.

Only a few months after the RSO was introduced into service the development of an armed version began.

Initial designs were for the gun to be unloaded by a collapsible crane each time it was to be fired, however the Wehrmacht insisted on a gun that was permanently mounted on the vehicle.

|

| An RSO truck towing a 105mm howitzer |

The development was carried out by Steyr in 1942 and resulted in the RSO Pak40 which was armed with a 7.5cm Pak 40/4 gun that could traverse 360 degrees.

It had a lightly armoured cab and collapsible sides on the cargo deck to provide a fighting deck for the gun crew. The result was a lightweight, cheap to produce, and highly mobile infantry anti-tank weapon.

Although the RSO Pak 40 provided improved mobility in the field it was not popular with the crews because:

- It was slow, noisy and the engine had a tendency to overheat in warm weather.

- The lack of armour provided little protection for the crew.

- The high silhouette made it difficult to conceal.

- The small fighting platform made it difficult to work in an effective manner and,

- The floor lockers for ammunition storage was difficult to access when the weapon was in use.

The vehicle earned the nickname 'Rollender Sarg Ost', a play on the RSO abbreviation which translates to 'rolling coffin east' reflecting the thoughts of the soldiers who operated it.

The exhibit was acquired from a collector in Germany and if you would like to know more about the RSO Pak40 you can follow the link to the museum video.

Developmental testing by the military began after a presentation of the prototypes designated as Type 62 in November 1938. Despite lacking four wheel drive, the vehicle proved very competent at manoeuvring its way over rough terrain, even in a direct comparison with a contemporary standard German Army 4x4, and the project was given the green light for further development.

Based heavily on the Volkswagen Beetle, the Type 62 prototype was further developed and in 1938 was known as the Type 82.

When Volkswagen production ceased at the end of the war, 50,435 Kübelwagen vehicles had been produced, and the vehicle had proven to be surprisingly useful, reliable, and durable.

The production number also explains how ubiquitous the vehicle has become for portraying the German Army in any film about World War II.

German Volkswagen Type 166 Schwimmwagen

The Volkswagen Schwimmwagen (literally "swimming car") is a light four-wheel drive amphibious car, used extensively by German ground forces during the Second World War.The first units to be equipped with the Schwimmwagen were the Waffen SS on the Eastern Front, followed by its issuing to Wehrmacht units in North Africa, and later on the Western and Italian Fronts, including Luftwaffe Fallschirmjäger and Field Divisions.

The Schwimmwagen used the engine and mechanicals of the VW Type 86 four-wheel drive prototype of the Kübelwagen, also used for the Type 87 four-wheel drive 'Kübel/Beetle' Command Car. The Type 128 prototype, was based on the full-length Kübelwagen with a wheelbase of 2.40 m (7 ft 10 in). |

| Perhaps one of the most famous pictures of a Schwimmwagen in action was these SS men operating with Kampfgruppe Peiper during the early days of the Ardennes Offensive in 1944 |

All Schwimmwagens were four-wheel drive in first gear (and reverse gears on some models) only and had ZF self-locking differentials on the front and rear axles.

As with the Kübelwagen, the Schwimmwagen had rear portal axles, which provided increased ground clearance, while at the same time reducing drive-line torque stresses with their gear reduction at the wheels. The Schwimmwagen had a top speed of 50 miles per hour (80 km/h) on land.

A total of 15,584 Type 166 Schwimmwagen were produced from 1941 through 1944; 14,276 at Fallersleben and 1,308 by Porsche; the VW 166 is the most-produced amphibious car in history. Only 189 are known by the Schwimmwagen Registry to remain today, and only 13 have survived without restoration work.

When crossing a body of water a screw propeller could be lowered down from the rear deck/engine cover. When in place a simple coupling provided drive straight from an extension of the engine's crankshaft. This meant that screw propulsion always drove forward.

The Schwimmwagen had a top speed of 10 km/h (6 mph) in the water. For reversing in the water there was the choice of using the standard equipment paddle or running the land drive in reverse, allowing the wheel-rotation to slowly take the vehicle back. The front wheels doubled up as rudders, so steering was done with the steering wheel both on land and on water. The Schwimmwagen could also be steered by the passengers using the paddle(s).

German Steyr 1500A Light Truck

Production of the Steyr 1500A Light truck began in 1941. The 1500A saw extensive use throughout the rest of World War II with various branches and formations in the Wehrmacht, including the Waffen-SS and the Afrika Korps.

Production ended after being cancelled in 1944, by which time Steyr had produced some 12,450 vehicles and Auto Union and Audi some 5,600, a total of 18,050 vehicles, many of which stayed in service until the end of the war.

The second variant was the command car version, designated the Kommandeurwagen Kfz 21. The command car version featured a radio transmitter and luxury interior and a fold-out roof. Some of the light truck bodies were also modified and used as field ambulances.

German Zundapp Motorcycle and Sidecar

The Zündapp KS 750 is a World War II-era motorcycle and sidecar combination developed for the German Wehrmacht before and during the Second World War, by the German company Zündapp G.m.b.H. After entering service in 1941, over 18,000 were built through 1944, and deployed on all major German battlefronts, for use in a variety of roles. The KS 750 was an integral design, with the rear wheel and the sidecar wheel shaft driven, powered by a 751 cc (45.8 cu in), overhead valve, flat twin engine.

German Kettenkrad SdKfz2 (Light Halftrack Gun Tractor)

The Sd.Kfz.2, better known as the Kleines Kettenkraftrad HK 101 or Kettenkrad (Ketten = chains/tracks, and krad = the military abbreviation of the German word Kraftrad, the administrative German term for motorcycle), started its life as a light tractor for airborne troops. The vehicle was designed to be delivered by Junkers Ju 52 aircraft, though not by parachute. The vehicle had the advantage of being the only gun tractor small enough to fit inside the hold of the Ju 52, and was the lightest mass-produced German military vehicle to use the complex Schachtellaufwerk overlapped and interleaved road wheels used on almost all German military half-tracked vehicles of World War II.

|

| Kettenkrad in Russia, Winter 1943/44. |

Most Kettenkrads saw service on the Eastern Front, where they were used to lay communication cables, pull heavy loads and carry soldiers through the deep Russian mud.

Later in the war, Kettenkrads were used as runway tugs for aircraft, especially for the Messerschmitt Me 262 jet fighter, and sometimes the Arado Ar 234 jet reconnaissance-bomber.

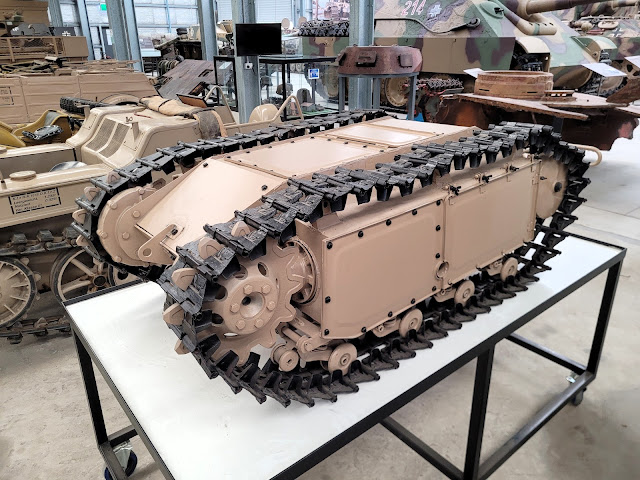

German "Goliath" Light Charge Carrier

Designed as single-use vehicles that were destroyed by the detonation of their warhead, they carried 60 or 100 kg (130 or 220 lb) of high explosives, depending on the model, and were intended to be used for multiple purposes, such as destroying tanks, disrupting dense infantry formations, and the demolition of buildings or bridges.

The result was the electric powered Leichter Ladungsträger SdKfz. 302 which was capable of carrying 60 kg (130 lb) of explosives.

|

| Captured Goliath carriers on Utah Beach after the D-Day landings |

The vehicle was steered remotely via a joystick control box. The control box was connected to the Goliath by a 650-metre (2,130 ft), long command cable connected to the rear of the vehicle. The cable transmitted power to the vehicle, controlled movement and steering and the detonation of the explosives.

This exhibit is an example of one of the early electric Goliaths and was a Western Front battlefield relic in a pretty poor state when the museum workshop set about restore it as seen here and with the remarkable process recorded in a series of videos in the link below.

German Hummel 15cm Self Propelled Gun The Hummel (German: "bumblebee") was a self-propelled gun based on the Geschützwagen III/IV chassis and armed with the 15 cm sFH 18/1 L/30 howitzer. It was used by the German Wehrmacht from early 1943 until the end of the war.

The full name of the Hummel was Panzerfeldhaubitze 18M auf Geschützwagen III/IV (Sf) Hummel, Sd.Kfz. 165.

The full name of the Hummel was Panzerfeldhaubitze 18M auf Geschützwagen III/IV (Sf) Hummel, Sd.Kfz. 165.

The Hummel crew travelled in the open-top armour plated high silhouette compartment. Protection against the weather could be provided by canvass covers.

The first option considered was mounting a 10.5 cm leFH 18 howitzer on a Panzer III chassis, rejected in favour of the same gun on a Panzer IV chassis. Only one prototype was built before the third design mounting the more powerful 15 cm sFH 18 L/30 howitzer was adopted on the specially designed Geschützwagen III/IV, which combined elements of both the Panzer III (driving and steering system) and the Panzer IV chassis (suspension, and engine). The same chassis was also used for the Nashorn tank destroyer.

The engine was moved to the centre of the vehicle to make room for an open-topped lightly armoured fighting compartment at the rear housing the gun breech and crew. Late models had a slightly redesigned driver compartment and front superstructure offering more room to the radio operator and driver.

Each battery normally consisted of six Hummels supplied by one Munitionsträger Hummel armoured ammunition carrier.

|

| A battery of Hummel howitzers in field position, Eastern Front, June – July 1943 |

In March 1943, the first batch of eight Hummel SPGs entered service, followed by another 46 in April. A fewmonths later they saw their first action during Operation Zitadelle (Citadel) in July 1943 on the Eastern Front.

As well as the Eastern Front, Hummels saw service in Greece, Italy and North West Europe until the end of the war, and a small number were captured by the Soviet forces and used against Axis forces in Hungary.

This exhibit was acquired as a destroyed relic and restored by the museum workshop.

German Pak 36 3.7cm Anti-Tank Gun

The Pak 36 (Panzerabwehrkanone 36) was a German anti-tank gun that fired a 3.7 cm calibre shell. It was the main anti-tank weapon of the Wehrmacht infantry units until mid-1941 when it was gradually replaced by the 5 cm Pak 38 gun.

|

| The Stielgranate 41 shaped charge. |

|

| German soldiers with the 3.7 cm Pak 36 anti-tank gun in Belgium, May 1940. |

.jpg) |

| Five German soldiers of the 89th Infantry Regiment with a 3.7 cm Pak 36 anti-tank gun on a Kharkov street during the First Battle of Kharkov in October 1941. |

By late 1941 however, the widespread introduction of the T-34 on the Eastern Front made the Pak 36 obsolete, considering its poor performance against it, leading to it being nicknamed "Heeresanklopfgerät" ('army door-knocking device') by German anti-tank crews for its inability to affect the T-34 aside from notifying its presence by futilely bouncing rounds off its armour, regardless of the angle or distance.

The advantages of the Pak 36 were its relative ease of handling and mobility where it could be brought into action very rapidly by as few as two men (it weighed only 432 kg); its good quality optical aiming devices; that it was small and easy to conceal and that it had a very high rate of fire.

In 1943, the introduction of the Stielgranate 41 shaped charge meant that the Pak 36 could now penetrate any armour, although the low velocity of the projectile limited its range. The Pak 36s, together with the new shaped charges, were issued to Fallschirmjäger units and other light troops. The gun's low weight meant that it could be easily moved by hand, and this mobility made it ideal for their purpose.

As the Pak 36 was gradually replaced, many were removed from their carriages and added to SdKfz 251 halftracks to be used as light anti-armour support.

This exhibit was acquired from Germany.

German Pak 38 5cm Anti-Tank Gun

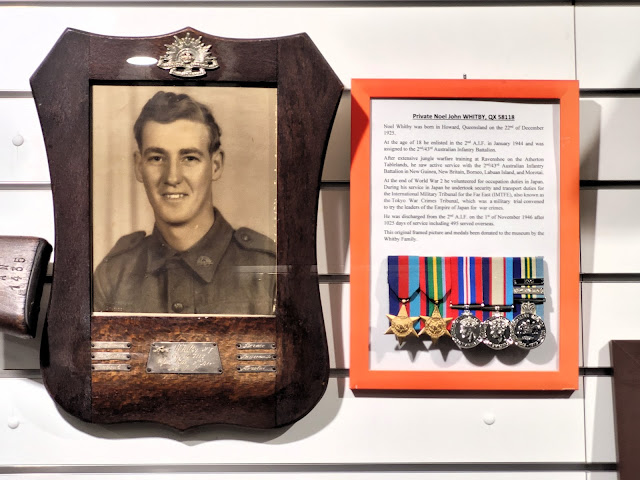

The 5 cm Pak 38 (L/60) (5 cm Panzerabwehrkanone 38 (L/60)) was a German anti-tank gun of 50 mm calibre. It was developed in 1938 by Rheinmetall-Borsig AG as a successor to the 3.7 cm Pak 36, and was in turn followed by the 7.5 cm Pak 40.Records held by the Australian War Memorial indicate that this gun was one of two Pak 38's captured intact by the 2/15 Battalion, 20th Brigade, 9th Division AIF during the Battle of El Alamein on the 28th-29th October 1942 and returned to Australia for proof trials, before becoming an army display gun and then later disposed of.

You can watch a video of the restoration of this special Australian memorial to the soldiers of the AIF that fought in North Africa in the link below.

German Pak 97/38 7.5cm Anti-Tank Gun

The Pak 97/38 (7.5 cm Panzerabwehrkanone 97/38 and 7,5 cm Panzerjägerkanone 97/38) was a German anti-tank gun used by the Wehrmacht in World War II. The gun was a combination of the barrel from the French Canon de 75 modèle 1897 fitted with a Swiss Solothurn muzzle brake and mounted on the carriage of the German 5 cm Pak 38.During the invasion of Poland and invasion of France the Wehrmacht captured thousands of 75 mm Model 1897 guns, built by the French arms manufacturer Schneider. These guns were adopted by the Germans as the 7.5 cm FK 97(p) and the 7.5 cm FK 231(f) and used in their original field artillery role.

Soon after the German invasion of the USSR in 1941, Wehrmacht units encountered the medium T-34 and the heavy KV Soviet tanks. The thick sloped armour of these vehicles gave them invulnerability against German towed 3.7 cm Pak 36 anti-tank guns. The situation led to requests for more powerful weapons that would be able to destroy them at normal combat ranges. Since Germany already had a suitable design, the 7.5 cm Pak 40, this weapon entered production and the first pieces were delivered in November 1941. However, until enough of these were manufactured, some expedient solution was required.

It was decided to solve the traverse and mobility problems by mounting the 75 mm barrel on the modern split trail carriage of the 5 cm Pak 38 anti-tank gun. To soften the recoil, the barrel was fitted with a large muzzle brake. The gun was primarily intended to use HEAT shells as the armour penetration of this type of ammunition does not depend on velocity.

The Pak 97/38 reached the battlefield in the summer of 1942. Despite moderate effectiveness and a violent recoil, it remained in service until the end of the war. The scale of use can be illustrated by the ammunition used: 37,800 HEAT shells in 1942 and 371,600 in 1943. On 1 March 1945 the Wehrmacht possessed 145 Pak 97/38 and FK 231(f) guns, although only 14 were employed by frontline units.

Ten barrels with shields were experimentally mounted on the Soviet T-26 light tank chassis, resulting in vehicles designated the 7.5 cm Pak 97/38(f) auf Pz.740(r). These self-propelled guns served with the 3rd Company of the 563rd Anti-Tank Battalion before being replaced by the Marder III on 1 March 1944.

The Pak 97/38 reached the battlefield in the summer of 1942. Despite moderate effectiveness and a violent recoil, it remained in service until the end of the war. The scale of use can be illustrated by the ammunition used: 37,800 HEAT shells in 1942 and 371,600 in 1943. On 1 March 1945 the Wehrmacht possessed 145 Pak 97/38 and FK 231(f) guns, although only 14 were employed by frontline units.

Ten barrels with shields were experimentally mounted on the Soviet T-26 light tank chassis, resulting in vehicles designated the 7.5 cm Pak 97/38(f) auf Pz.740(r). These self-propelled guns served with the 3rd Company of the 563rd Anti-Tank Battalion before being replaced by the Marder III on 1 March 1944.

The Pak 97/38 was produced using captured barrels and could fire capture French and Polish ammunition. Together with light weight, good mobility and sufficient anti-armour performance with HEAT shells it was regarded as a decent anti-tank weapon.

It had shortcomings, particularly its low muzzle velocity. Although it did not affect the armour piercing characteristics of its HEAT ammunition, it meant insufficient performance when firing regular AP shells and - because of difficulties in hitting small mobile targets - its low effective range of about 500 metres (550 yards) even with HEAT.

This exhibit was acquired in Finland.

Development of the Pak 40 began in 1939 with contracts being placed with Krupp and Rheinmetall to develop a 7.5 cm anti-tank gun. Priority of the project was initially low, but following the invasion of the USSR in 1941 and the unexpected appearance of heavily armoured Soviet tanks such as the T-34 and KV-1, it was given an increased priority. The first pre-production guns were delivered in November 1941.

After the war, the Pak 40 remained in service in several European armies, including Albania, Bulgaria, Czechoslovakia, Finland, Norway, Hungary and Romania. About 23,500 Pak 40s were produced, and about 6,000 more were used to arm tank destroyers.

The weapon was effective against almost every Allied tank until the end of the war. The Pak 40 was much heavier than the 5 cm Pak 38; its decreased mobility meant that it was difficult or even impossible to move without an artillery tractor on boggy ground.

The Pak 40 was first used in Russia where it was needed to combat the newest Soviet tanks. It was designed to fire the same low-capacity APCBC, HE and HL projectiles which had been standardized for use in the long barrelled Kampfwagenkanone KwK 40 tank-mounted guns. In addition, there was an APCR shot (Panzergranate 40) for the Pak 40, a munition which - reliant on supplies of tungsten - eventually became very scarce.

This exhibit was acquired from Bulgaria.

The Pak 40 was first used in Russia where it was needed to combat the newest Soviet tanks. It was designed to fire the same low-capacity APCBC, HE and HL projectiles which had been standardized for use in the long barrelled Kampfwagenkanone KwK 40 tank-mounted guns. In addition, there was an APCR shot (Panzergranate 40) for the Pak 40, a munition which - reliant on supplies of tungsten - eventually became very scarce.

German 15cm Nebelwerfer 41

The 15 cm Nebelwerfer 41 was a six-tube rocket launcher mounted on a modified 3.7 cm anti-tank gun carriage. It was one of a series of nebelwerfers developed and used prior to and during World War II by the German Army.The name Nebelwerfer is best translated as "smoke mortar" and it was given the name to mislead observers from the League of Nations into thinking that it was merely a device for creating a smoke screen and not a weapon to breach the Treaty of Versailles.

|

| A 15 cm Nebelwerfer 41 launcher being reloaded |

The explosives were contained at the rear of the rocket. This meant that the rocket would still be above the ground when it detonated which increased the blast and fragmentation effect of the exploding rocket.

The Nebelwerfer 41 was capable of firing high-explosive shells, incendiary projectiles chemical warfare rockets and smoke. The chemical warfare rockets were stockpiled but are said to have not been used operationally.

The barrels do not have the normal breech or firing mechanism that other weapons have. Each rocket was manually loaded into the lower end of the barrel, as seen above, and held in place by a locking clip. An electrical sparking device is then attached to each rocket and connected to a manually operated ERZ39 initiator which allowed the operator to fire the six rockets individually from 15 to 20 metres away to avoid the exhaust flames.

After firing, a long streak of smoke was visible from a considerable distance, leaving the Nebelwerfer vulnerable to counter-battery fire. It was therefore necessary to relocate the launcher and crew as soon as possible after firing.

This exhibit was acquired as a battlefield relic from the Eastern Front and was restored to its current condition in the museum workshop.

German 7.5cm Le IG 18 (Light Infantry Gun)

In the aftermath of World War I, every military force immediately began to assess what they thought was most important to improve their arsenals for a future war. For Germany, one thing they felt was lacking was a light howitzer that could be incorporated into infantry units, mobile enough to remain with the front line units in an advance to provide easy and immediate supporting fire.

The Rheinmetall company designed the 7.5 cm Leichtes Infanteriegeschütz 18 (7.5 cm le.IG 18) in 1927, despite the terms of the 1918 Versailles Treaty prohibiting the Germans from developing new weapons; and to help deceive the League of Nations, the numerals 18 were incorporated into its official title to imply that the gun had been in production and service in 1918.

The 7.5 cm le.GebIG 18 fitted a 12-pound (6 kg) high-explosive shell out to 4,000 metres (4,375 yards) and was capable of both direct and indirect fire.

The mechanical operation of the gun is rather unusual for an artillery piece, with a fixed breech and a barrel which tips up from the muzzle for loading and ejection, not as it happens conveying any particular advantage, but also not incurring any particular weakness and proved quite satisfactory in practice.

There was a mountain gun variant, the 7.5 cm le.GebIG 18. that could be broken down into six to ten packs, the heaviest weighing 74.9 kg. These were typically assigned at two to each mountain battalion. Only six 7.5 cm le.IG 18F were manufactured in 1939.

There was an airborne gun variant, capable of being broken down into four 140 kg loads and had smaller wheels and no shield.

There was also an infantry support gun variant, known as the 7.5 cm Infanteriegeschütz L/13 and designed as a replacement for the le.IG 18, which could be broken into four to six loads. However, though prototypes were tested, the German army felt that it did not improve on the existing design sufficiently to merit introduction and the army stayed with the earlier gun.

This exhibit was acquired from Czechoslovakia as a battlefield relic and restored to its current condition by the museum workshop.

Czech Howitzer Model vz 14/19

The Skoda houfnice vz 14 ("Howitzer model 1914") and Skoda houfnice vz 14/19 ("Howitzer model 1914/1919") were 100 mm (3.93-inch) field howitzers made in Czechoslovakia by the Skoda works.The vz 14/19 was an improved version of the vz 14 and was created in 1919 after World War I with a longer barrel offering greater range, and some versions had rubber tires so they could be pulled by trucks but most retained wooden spoked wheels so they could be pulled by mule teams.

Germany captured a vz 14/19 when they conquered Poland and absorbed Czechoslovakia and later seized additional guns while fighting in Italy, Hungary, Yugoslavia and Greece.

Due to their age, the howitzers were relegated to second line service and incorporated into defensive lines and fortifications after 1942.

This exhibit was acquired from Belgium, and it was captured by the Germans during World War II, repainted and modified in a number of ways including being fitted with non-original shield, a muzzle break, a British 25-pounder firing platform, and Norwegian tyres.

German 10.5cm leFH 16 Howitzer

The 10.5 cm leichte Feldhaubitze 16 (10.5 cm leFH 16) was a field howitzer used by Germany in World War I and World War II.It shared the same carriage as the 7.7 cm FK 16 and was pulled by a team of horses or a vehicle. Its weight meant that it was not easy for the crew to move quickly.

German 10.5cm leFH 18 Howitzer

The 10.5 cm leFH 18 was the standard divisional field howitzer used by the Wehrmacht during the Second World War. It was designed and developed by Rheinmetall in 1929-30 and entered service with the Wehrmacht in 1935. Generally it did not equip independent artillery battalions until after the Battle of Stalingrad in 1943.

Before 1938 the leFH 18 was exported to Hungary and Spain. Fifty-three were exported to Finland, where they were known as 105 H 33. One hundred and sixty-six were exported to Bulgaria in 1943 and 1944. One hundred and forty-two were purchased by Sweden between 1939 and 1942, designating it Haubits m/39.

It had a heavy, simple breech mechanism with a hydro-pneumatic recoils system. The 10.5cm leFH 18 had wood-spoked or pressed steel wheels. The former were only suitable for horse traction.

Initially it was not fitted with a muzzle break. In 1941 a muzzle break was fitted to allow longer range charges to be fired. This increased the range by about 1,800 yards and was known as the leFH 18M.

In March 1942 a requirement was issued for a lighter howitzer. This led to a second modification, known as the leFH 18/40. This modification consisted of mounting the barrel of an leFH 18M on the carriage of a 7.5cm Pak 40 anti-tank gun. The new carriage increased the rate of fire as well as making the howitzer lighter. Additionally a more efficient muzzle break was added, decreasing the recoil. Ballistically, the 10.5cm leFH 18M and the leFH 18/40 are identical.

This exhibit was acquired from Norway.

German 15cm sFH 18 Howitzer

The 15 cm schwere Feldhaubitze 18 or sFH 18 (German: "heavy field howitzer, model 18"), was the basic German division-level heavy howitzer during the Second World War, serving alongside the smaller but more numerous 10.5 cm leFH 18.Shortly after coming to power in the early 1930's, Adolf Hitler commenced a secret re-arming program designed to undermine the terms of the Treaty of Versailles, which forbid Germany to rearm. The sFH 18 was disguised to look like the WWI artillery pieces that Germany had been allowed to keep. Although incorporating improvements it was generally outdated compared to the weapons it faced. It was the first artillery piece equipped with rocket assisted ammunition to increase range.

The gun originated with a contest between Rheinmetall and Krupp, both of whom entered several designs that were all considered unsatisfactory for one reason or another. In the end the army decided the solution was to combine the best features of both designs, using the Rheinmetall gun on a Krupp carriage.

The gun was officially introduced into service on 23 May 1935, and by the outbreak of war the Wehrmacht had about 1,353 of these guns in service. Production continued throughout the war, reaching a peak of 2,295 guns in 1944.

The Flak 30 (Flugzeugabwehrkanone 30) and improved Flak 38 were 20 mm anti-aircraft guns used by various German forces throughout World War II. It was not only the primary German light anti-aircraft gun but by far the most numerously produced German artillery piece throughout the war.

The main problem with the design was the rate of fire of 120 RPM (rounds per minute) which was not particularly fast for a weapon of this calibre. Rheinmetall responded with the 2 cm Flak 38, which was otherwise similar but increased the rate of fire by 220 RPM and slightly lowered overall weight to 420 kg. The Flak 38 was accepted as the standard Army gun in 1939, and by the Kriegsmarine as the C/38.

German 2cm Flakvierling 38 Anti-Aircraft Gun

The improved Flak 38 20 mm anti-aircraft guns was produced in a variety of models, including the Flakvierling 38. The term vierling means literally 'quadruplet' and refers to a mounting carrying four guns.German 3.7cm Flak 36 Anti-Aircraft Gun

The gun's ballistic characteristics were not changed, although the practical rate of fire was raised to 120 rpm (180 rpm theoretical). A new, simplified sighting system introduced the next year produced the otherwise-identical 3.7 cm Flak 37. The Flak 36/37 were the most-produced variants of the weapon.

The 3.7 cm Flak 43 was a dramatic improvement over older models. A new gas-operated breech increased the practical firing rate to 150 RPM, while at the same time dropping in weight to 1,250 kg (2,760 lb) in combat, and 2,000 kg (4,400 lb) in transport.

It was also produced in a twin-gun mount, the 3.7 cm Flakzwilling 43, although this version was considered somewhat unwieldy and top-heavy.

This exhibit was acquired from the USA.

German 8.8cm Flak 18/36/37 Anti-Aircraft Gun

The 8.8 cm Flak 18/36/37/41 was a German 88 mm anti-aircraft and anti-tank artillery gun, developed in the 1930s and was widely used by Germany throughout World War II, universally known as the "eight-eight" by the Allies.  |

| 8.8cm Flak 36 being emplaced, with both bogies already detached |

The Flak 18 was available in small numbers when Germany intervened in the Spanish Civil War. It quickly proved to be the best anti-aircraft weapon then available. The flak detachment proved accurate and versatile in combat against mainly land targets, the high muzzle velocity and large calibre made it an excellent long-range anti-vehicle and anti-bunker weapon. Many improvements were identified as a result of use in the Spanish Civil War and were later incorporated into the Flak 36.

|

| An 88 mm gun in a direct fire role, USSR, 1942 |

The German Condor Legion made extensive use of the 8.8 cm Flak 18 in the Spanish Civil War, where its usefulness as an anti-tank weapon and general artillery piece exceeded its role as an anti-aircraft gun. For the Battle of France in 1940, the army was supported by eighty-eights deployed in twenty-four mixed flak battalions.

During the North African campaign, Rommel made the most effective use of the weapon, as he lured tanks of the British Eighth Army into traps by baiting them with apparently retreating German panzers.

The 8.8 cm Flak was arguably most effective in the flat and open terrain of Libya, Egypt and on the Eastern Front but were more limited in the topography of Italy and France.

This gun is a Flak 36 and was acquired from a dealer in Europe.

German 8cm Granatwerfer 34

The 8 cm Granatwerfer 34 (8 cm GrW 34) was the standard German infantry mortar throughout World War II, and was designed and developed by Rheinmetall-Borsig AG, being basically an upgraded version of the French Brandt mle 27/31 81mm mortar.The GrW 34 mortar was an indirect fire weapon used for close fire support with a variety of ammunition and was relatively simple to operate.

A mortar crew consisted of three members, the gunner who aimed the weapon, the assistant gunner who loaded the round at the command of the gunner, and the ammunition man prepared and handed over the ammunition to the assistant gunner.

After the gunner has aimed the mortar, the assistant gunner slides a purpose designed round, fins first, down the tube which is generally set at an angle of between 45 and 65 degrees to the ground with the higher angle used for shorter firing distances, on reaching the base, a fixed pin in the mortar detonates a propellant change (located at the axis of the fins); the resulting blast is channelled out via the holes in the shaft between the main body and the fins. As the gases from the detonation expand, they are prevented from further expansion by the walls of the mortar tube and the actual round itself. The path of least resistance is to move the round back up the tube.

.jpg) |

| A four-man crew of Waffen-SS soldiers firing on Yugoslavian partisans, December 1943. |

The maximum range was 2.4 km (1.5 miles), with the more important effective range being between 400-1,200 metres (440-1.310 yards).

German 12cm Granatwerfer 42

During World War II the Soviet M1938 mortars were captured and utilised by the Germans in large numbers on the Eastern Front, and in German use, the captured Soviet mortar was given the designation 12 cm Granatwerfer 378 (r).

Their impressive performance lead to the development of the 12cm Granatwerfer 42 (Grenade Thrower Model 42) by Germany during 1942. Its official designation was 12 cm GrW 42.

The GrW 42 remained in service until the end of the war and gave German infantry units a close support weapon with a heavier performance than the other mortars used in general service at the time.

The exhibit was acquired from the UK.

German 80cm Railway Gun Shell Case

In early 1937 after preliminary work by Krupp AG, the leading German steelworks and armaments manufacturer, Hitler approved its manufacture in the hope the gun would be ready to demolish the Maginot Line defences by the spring of 1940.

The manufacture of the cannon proved harder than had been anticipated and it wasn't until 1941 that the first barrel was test fired. It was nearly a year later before the full gun was finally tested in the presence of Hitler.

|

| The Krupp 80cm Kanone (E) Schwerer Gustav / Dora being readied for a test firing on 19 March 1943 at Rügenwalde, Germany in the presence of Adolf Hitler and Albert Speer. |

The first 80cm gun completed was given the name 'Schwere Gustav' in honour of its originator Gustav Krupp. According to the tradition of Krupp, no payment was made for the first weapon. The second gun named 'Dora', after the wife of the chief design engineer, was produced at a cost of seven million Reichsmark.

The first operational service of an 80cm gun was at the siege of Sevastopol in July 1942 where it successfully destroyed a number of fortifications. The gun was then sent to the besieged city of Leningrad, but before it could be set up the Russian offensive forced its withdrawal. It would next see service in 1944 when it fired approximately 30 shells during the Warsaw siege.

As the German war situation deteriorated the 80cm guns were withdrawn from the front line to Germany where they were destroyed to prevent them falling into the hands of the Allies.

The 80cm shell case on display was located in Germany where it was being used as a water storage container.

German Portable Machine Gun Pillbox

In 1943 the German Army first used portable machine gun pill boxes (bunkers) in defensive positions against the Russians on the Eastern Front. The pill boxes were known by the nickname of 'Armoured Crabs' because of their appearance.

Their success on the Eastern Front lead them to be used in large numbers by the Germans in defensive positions in preparation for the D-Day Invasion and in the Italian Campaign.

When set up, multiple pill boxes were sighted together with interlocking fields of fire from other pill boxes because of their limited 60 degree arc of fire.

The 3 ton cast-steel pill boxes were 1.70m (5.6 ft) wide and had an overall height of 1.82m (6ft). When emplaced, less than 1 metre protruded above ground.